Brückner One

The comprehensive solution from Brückner Maschinenbau and Brückner Servtec

The comprehensive solution from Brückner Maschinenbau and Brückner Servtec enables ground-breaking new ways for more efficient and flexible production and is also a one-stop solution that supports all aspects of the line and its services.

It convinces with industry-proven service products on a new, digital level.

Brückner Maschinenbau uses new technologies and strategies to improve the efficiency and flexibility of production processes. We are offering a complete solution that covers all aspects of the production line and its associated services. These solutions have been tested and proven in the industry and are now being enhanced with digital capabilities.

For the Brückner One service package from Brückner Servtec, please click on the following link to find out more.

Production

Industry 4.0 meets innovative plant operation

| PRODUCTION | Included | Optional |

| ♦ Integrated Machine Control | x | |

| ♦ Cockpit | x | |

| ♦ Advanced Viscosity Display | x | |

| ♦ Operating Point Assistant | x | |

| ♦ Thickness Controll Engine - Basic Functions | x | |

| ♦ DieBolt Tool |

free till |

|

| ♦ Thickness Map (TCE) | free till end of warranty |

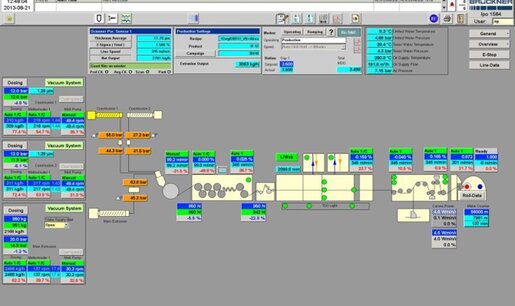

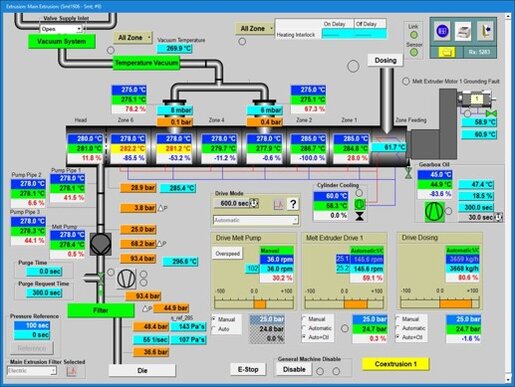

Integrated Machine Control

The Heart of the system and the operating software of the machine provides all the features you need for a successful production.

- Complete system control: Intuitive operation enables control over all aspects of the system from the outset.

- Fast production start-up: Seamless commissioning until full production output is reached.

- In-depth troubleshooting: Comprehensive diagnostics in the event of faults, including circuit diagram display and customizable trends for fast solutions.

- Flexible production recipe management: Simple change of production settings by loading recipes, without manual intervention.

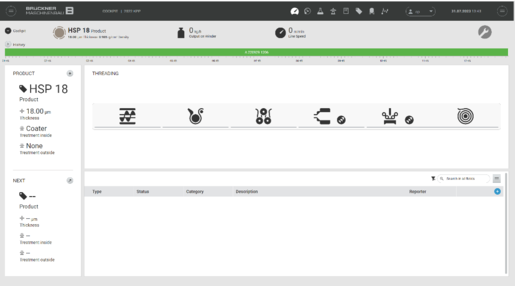

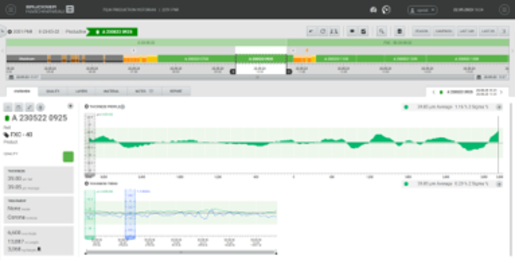

Cockpit

The cockpit displays the production status and quality level of the last roll. It saves the history of the last 12 hours and simultaneously manages the service tasks and the next product list. It offers a live KPI view. New applications can be started via this cockpit thanks to direct quick links.

Your benefits:

- Most relevant information in one page

- Enhancement of better collaboration

Advanced Viscosity Display

The Advanced Viscosity Display shorten reaction time on film property changes and offers the advantage to compare different lines. Process changes will be visible sooner and offers a longer lifetime of the TFE Lock rollers due to optimized working point.

Your benefits:

- Optimized Quality control

- Reduction of laboratory time

- Less maintenance costs

- Easier line handling

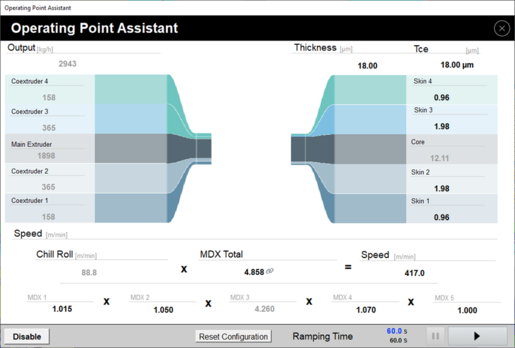

Operating Point Assistant

The Operating Point Assistant is a software module that supports the intuitive and safe change of speed, thickness and output of a stretching line.

By changing one parameter and automatically adjusted machine settings the software offers:

- Fail save operation

- Less complexity of production

- Faster product change

DieBolt Tool

- With the DieBoltTool the system will find the time of the best profile in the past 8 hours production.

- It shows then the current profile and the historical profile to compare the thicknesses.

- Also the difference of die bolt temperatures is displayed.

- It is possible to set the old target temperatures and thus very quickly restore the previous good production.

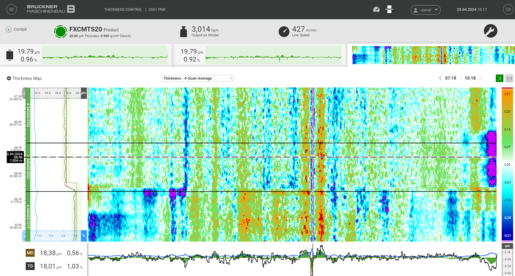

Thickness Map

- The saved historical profiles can be displayed graphically as a color map. The thickness is color coded.

- The thickness distribution of individual rolls can be recorded at a glance, and longer periods of time can also be displayed.

- The user can do easily long-term process analysis. It is also possible to display MD trends and TD profiles within the map.

Analytics

Performance tracking of your line with one click

| ANALYTICS | Included | Optional |

| ♦ Recipe Manager | x | |

| ♦ Product Manager | x | |

| ♦ Raw Material Manager | x | |

| ♦ Film Production Historian (FPH) - Basic Functions | x | |

| ♦ Energy Monitor | Upon request | |

| ♦ Advanced FPH Tool | free till end of warranty |

|

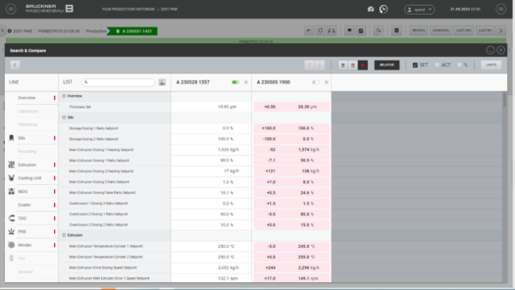

| ♦ Comparison Tool | free till end of warranty |

|

| ♦ Uptime Tool | free till end of warranty |

|

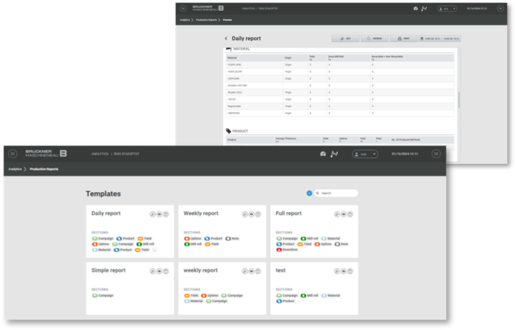

| ♦ Reporting Tool | free till end of warranty |

|

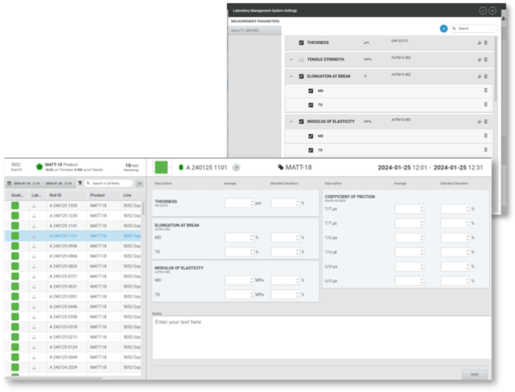

| ♦ Laboratory Tool | free till end of warranty |

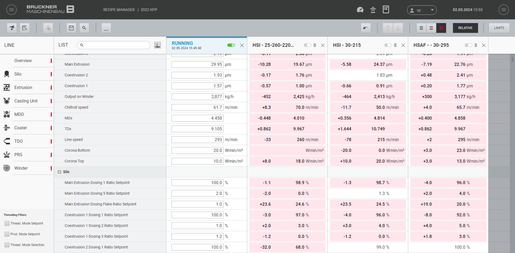

Recipe Manager

The feature saves and manages existing recipes. It can generate recipes from historic mill rolls or current production parameters, offers easy customisation options and then sends the corresponding recipe to the production line with a single click.

It also offers a comparison function for different recipes.

Your benefits:

- Systematic analysis and setup

- Improved uptime and process

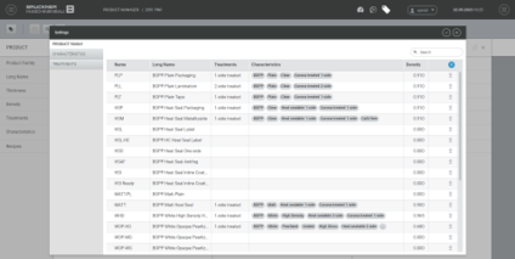

Product Manager

The product manager facilitates the definition and management of end products. The user can either define products or there is a list of predefined products that are added automatically.

The product is in focus and brings together materials, recipes and machine data.

As customer values in the software, this tool provides product-related KPIs and statistics and gives the machine data a business meaning.

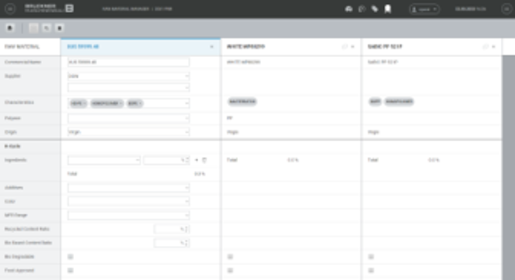

Raw Material Manager

The raw material manager facilitates the definition and management of the materials. It integrates with the rest of the applications:

- The materials are used in other apps

- Managing materials is reflected in the apps that are using materials

This toll allows the user to track the material from the silo to the layer of the film that was produced.

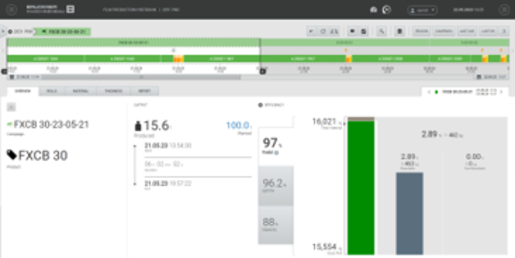

Film Production Historian (FPH) - Basic Functions

This function offers the advantage of visualising the historical production data of a line.

Your benefits:

- Explore production information since the line was started

- View the most relevant data for campaigns, rolls and more

- Display detailed information on relevant KPIs and material consumption

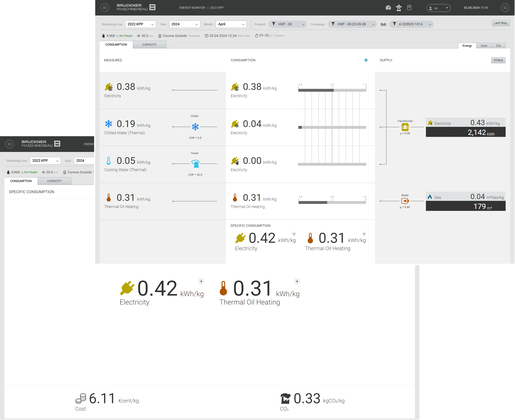

Energy Monitor

The energy monitor tracks and analyzes energy consumption of the film production process. Energy consumption is shown specifically,

i.e. per kg of film produced, and divided into electrical and thermal energy consumption.

Your benefits:

- Helps identifying saving potentials

- Accurate feedback of taken measures

- Energy cost calculation per product

- Increased awareness on energy

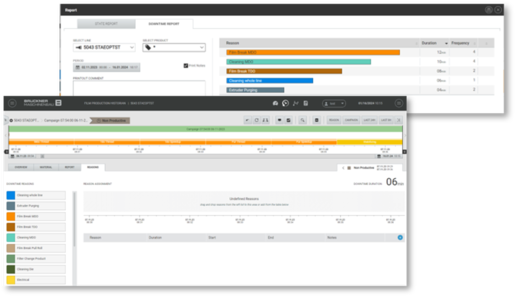

Advanced Film Production Historian (FPH) Tool

The Advanced Film Production Historian (FPH) tool displays aggregated data for any time period. It offers the possibility to select random time periods, yield and uptime KPIs with details are available and it shows production statistics.

Efficiency information is also available for campaigns, including revenue and uptime KPIs with details and capacity KPIs. For each campaign, the tool offers the possibility to compare KPIs set for that specific campaign.

Maintenance

Maximise your production time

| MAINTENANCE | Included | Optional |

| ♦ Gear Box Analysis | Upon request | |

| ♦ Roller Bearing Analysis | Upon request | |

| ♦ Roller Roundness Analysis on Nip Rollers | Upon request | |

| ♦ Roller Chain Condition Monitoring | Upon request |

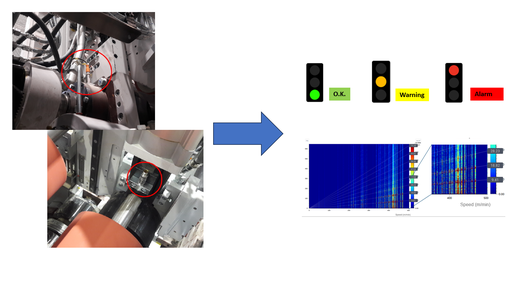

Gear Box Analysis

This is a standard tool for the main extruder. By means of permanent (24/7) monitoring of vibrations, the feature enables early detection of problems or incipient component failures such as misalignment of motor and gearbox, motor or gearbox bearing failure or increased wear on gearboxes. A reporting tool also helps to identify parts that need to be checked.

Your benefits:

- Reduce efforts and costs as less inspections are needed

- Avoid risk of unplanned machine downtime and production loss

- Less efforts and more convenience

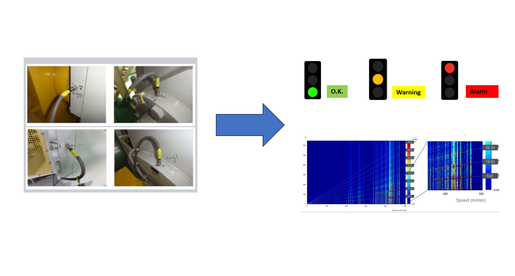

Roller Bearing Analysis

Vibration sensors detect the vibration level on the bearings of certain stretch and nip rollers (MDO) or corona and nip rollers (Pull Roll).

An early warning system uses real-time data analysis to indicate the condition of the bearings and the roll surface. In the requested expert‘s report the root cause of the vibrations is identified.

Your benefits:

- Reduction of effort and costs through better planning of maintenance activities

- Avoid risk of unplanned machine downtime and production loss

- Less efforts and more convenience

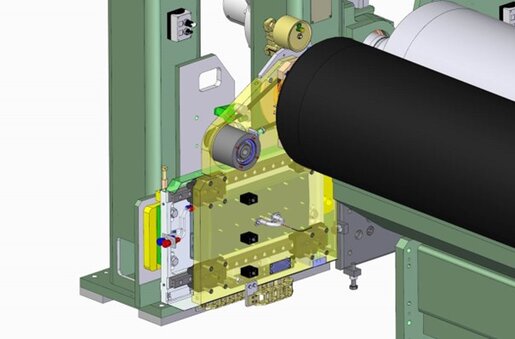

Roller Roundness Analysis on Nip Rollers

This function allows to roughly classify the roundndess of the Nip rollers and the Corona rollers with regard to excess wear. As a consequence, the specific roller (nip vs. corona) which is causing harmful vibrations can be identified. Some suggestions such as parametrization of the LiNip system, selection of the damping algorithm and parameters and possible exchange of rollers can be drawn. As a prerequisite, the line must be equipped with a LiNip system.

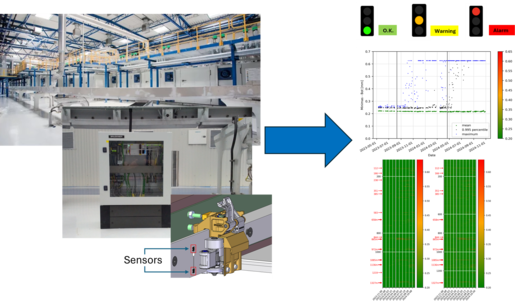

Roller Chain Condition Monitoring

Roller Chain Diagnosis is used to evaluate the distance between the rail and the chain rollers and the vibration level of the chain. Stiff bushings and missing or misshapen rollers are detected. An early warning system in the control unit indicates when action is needed.

Your benefits:

- Reduce maintenance efforts and costs

- Better plan of maintenance activities

- Avoid risk of machine downtime and production loss

- Less effort, more convenience