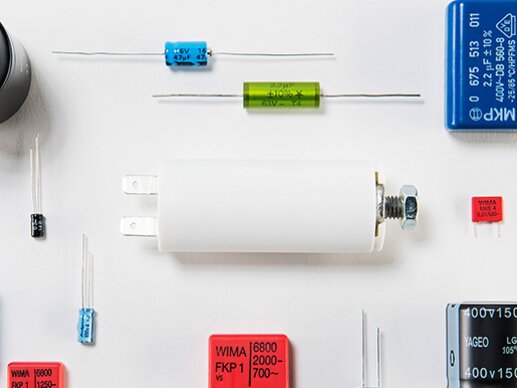

Capacitors

Expertise in both sequential and simultaneous stretching

The preferred choice of raw materials for capacitor films are polypropylene (PP) and polyethylene terephthalate (PET). PP is independent of frequency and has a high impulse stability – therefore it can be used in AC and DC applications.

Compared to this, PET is heavily dependent on frequency due to its high loss factor and so it is mainly used in DC applications. Both types of capacitor film are produced by biaxial stretching where a more perfect crystalline structure is formed and the dielectric strength can be increased.

- Sequential stretching process for highest film quality: Optimised surface roughness, good self-healing effect

- Simultaneous stretching process: Growing demand for quite special and high-value applications

• Low MD shrinkage even at low thickness

• Higher potential for thinnest film due to high stretching ratios

Extremely thin films

and high-temperature films for future-oriented EV applications

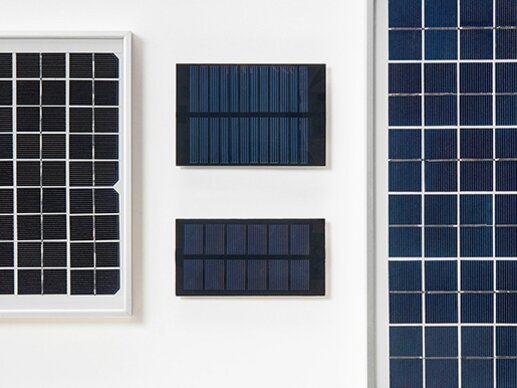

High energy density film

for renewable energy applications in the power industry

Close cooperation with raw material suppliers

- High break down voltage

- Material optimisation for the sequential as well as the simultaneous stretching process

| Film Type | Thickness Range |

|---|---|

| Capacitor film for metallising | 2 - 12 µm |

| Capacitor film for impregnation | 10 - 12 µm |