New materials for high temperature capacitors

Innovative polymer-based films or coextruded polymers with high voltage and temperature resistance

“HoTeKo” is a government-funded project in the period between April 2015 and March 2017. Within this project Brückner has been developing a new dielectric film with the partners Kement, Lenze, ZF and IVV Freising for high temperature stability and electrical strength for DC link film capacitors. With Kemet’s, Lenze’s and ZF‘s requirements on the capacitor and/or the power electronics, some dielectric materials were chosen to extrude and stretch on Brückner’s KARO IV lab stretcher. Brückner selected two suitable materials according to the characterization in the laboratories regarding mechanical, electrical and dielectrical properties.

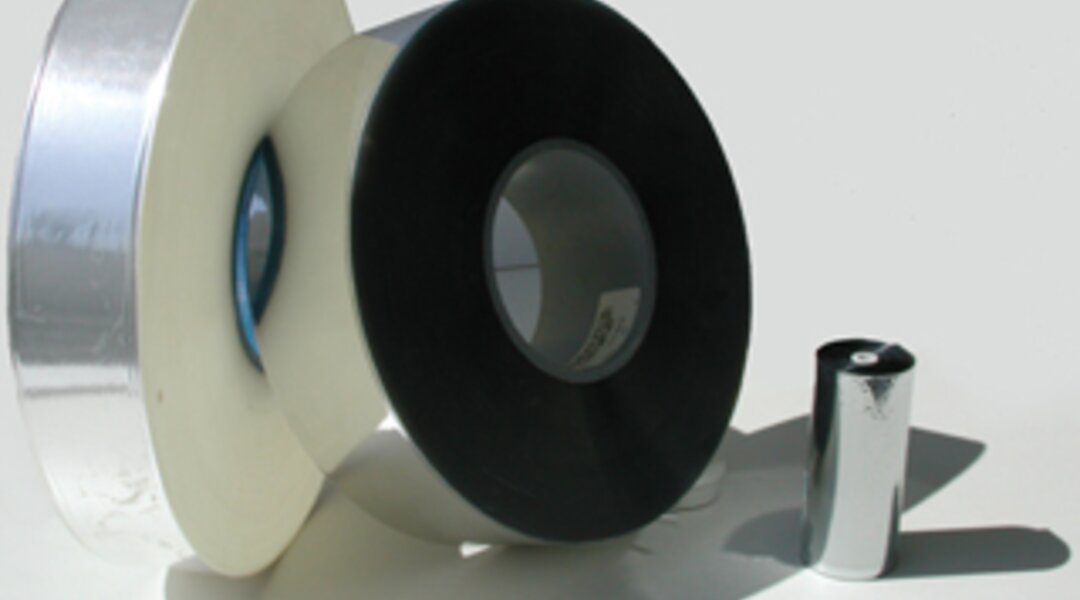

After finding the right stretching conditions, the up-scaling process from the discontinuous lab stretcher to the continuous pilot line started in July 2015. The goal of the project from Brückner’s perspective is to get sample rolls of the pilot line for metallization. After that the partners can test the new dielectric film inside the capacitor and power electronics to confirm the good results of the new capacitor films.