Latest equipment for added value BOPET films

Brückner`s recently commissioned 8.2m BOPET line comes up with a trend-setting 2-gap MDO stretching unit. Due to a significantly higher stretching ratio (between 4.5 and 4.7) compared to the benchmark technology, our customer Changzhou Zhongheng New Material achieves a higher production speed at a much lower pinning speed. The fact, that no additional costly pinning agents are necessary is a clear benefit for Changzhou Zhongheng New Material.

Furthermore the 2-gap stretching leads to high uptime, high output and high stability - all in all: utmost efficiency. As a matter of course the produced BOPET film (between 8µm and 36 µm) meets highest international quality standards. The on-time commissioning, the successful start up, and the top quality of the produced film paved the way for a further co-operation between Changzhou Zhongheng New Material and Brückner

All this has attracted great interest within the international film producers` community, particularly the fact that constant line speeds up to 450 m/min have come into reach.

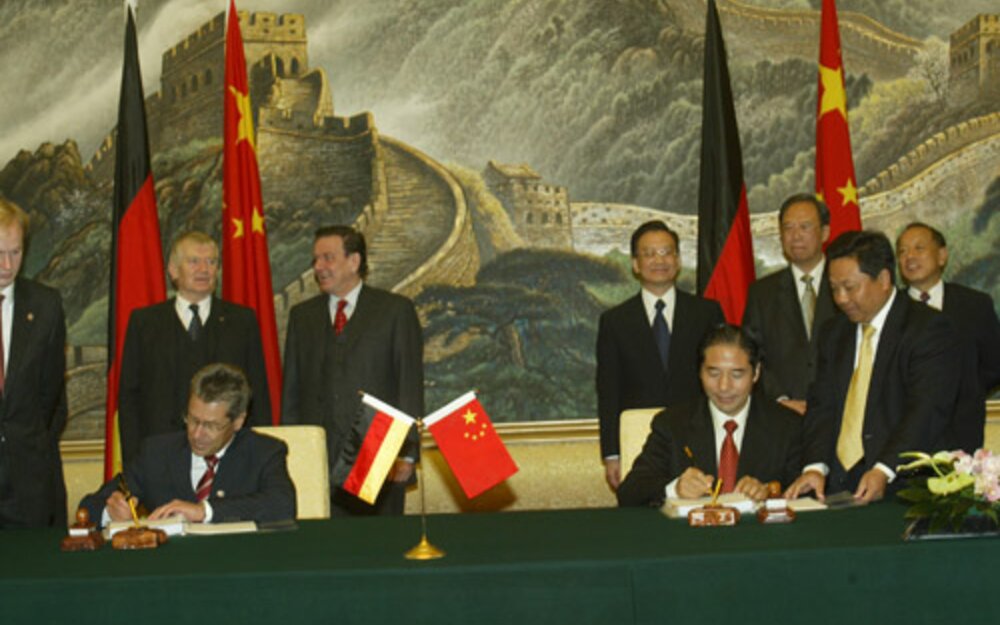

The contract for the outstanding line between one of China 's leading film producers Jiangyin Shenda Group (the mother company of Changzhou Zhongheng New Material) and Brückner was signed at that time at the Great Hall of the People in Beijing , and attended by the Chinese Premier Wen Jiabao and the former German Chancellor Gerhard Schröder.

More benefits for producers of high value BOPET films from additional Brückner highlights

Besides the 2-gap stretching, Brückner customers also profit by:

Twin screw technology for the main and the co-extrusion: no pre-drying needed - big cost savings potential

Trendsetting drive system for excellent optical quality Energy saving design: heat recovery systems, reusing exhaust heat

Advanced thickness measurement for brilliant thickness profiles

Utmost flexibility: film thickness up to 400µm (sequential) or 250µm (simultaneous, contact-free stretched) for A-grade optical films