FOROP commissions their first Brückner hybrid line

30 Sep 2024

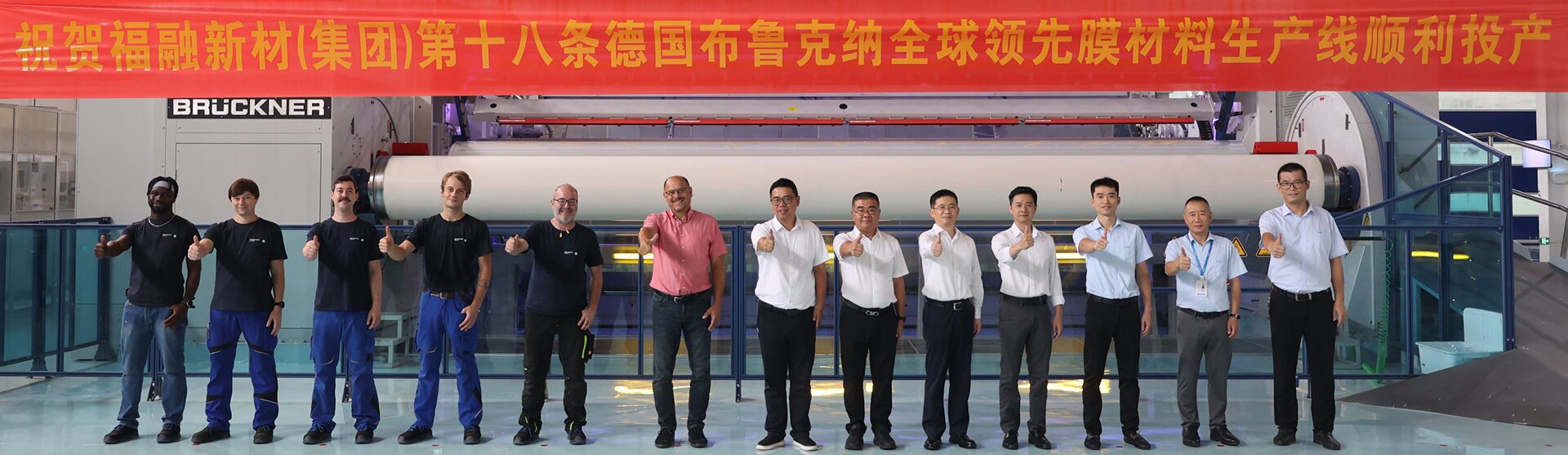

Our long-standing Chinese customer is delighted with the start-up of their 18th Brückner line

With their ongoing investments and the start-up of their first Brückner hybrid line, Forop Advanced Materials is celebrating a strategically important milestone. Thanks to now 18 Brückner lines it total and an annual production capacity of 800,000 tonnes, FOROP can meet the increasing demand in the Chinese inland and abroad.

The new 8.7 metre hybrid line can process both PP and PE raw materials. With its constant production speed of 600 m/min, it is one of the most efficient lines in the Asian region. FOROP is also pursuing their far-reaching sustainability goals and has therefore installed an exhaust air purification system around the production line, which cleans all the exhaust air from the production hall thanks to an air scrubber and ozone catalyst.

It is the last of four Brückner lines, which were recently commissioned at their new site in Fuqing. Four more will follow over the next two years. Josef Haslinger, Head of Sales China at Brückner Maschinenbau, appreciates the excellent and long-standing cooperation between the two companies: ‘The trust that has been built up had a significant influence on the successful start-up. We are delighted to have played a key role in FOROP's success over the past few years.’

For project manager Christoph Bombik, the joint achievement of all colleagues on site will be remembered: ‘This is a joint effort by our various companies – be it the business units Brückner Maschinenbau and Brückner Servtec, as well as our platform companies from China, Thailand and India and the FOROP team on site. Thanks to the outstanding team effort, we were able to successfully commission this line.’