请注意:本网站仅提供英文版本。

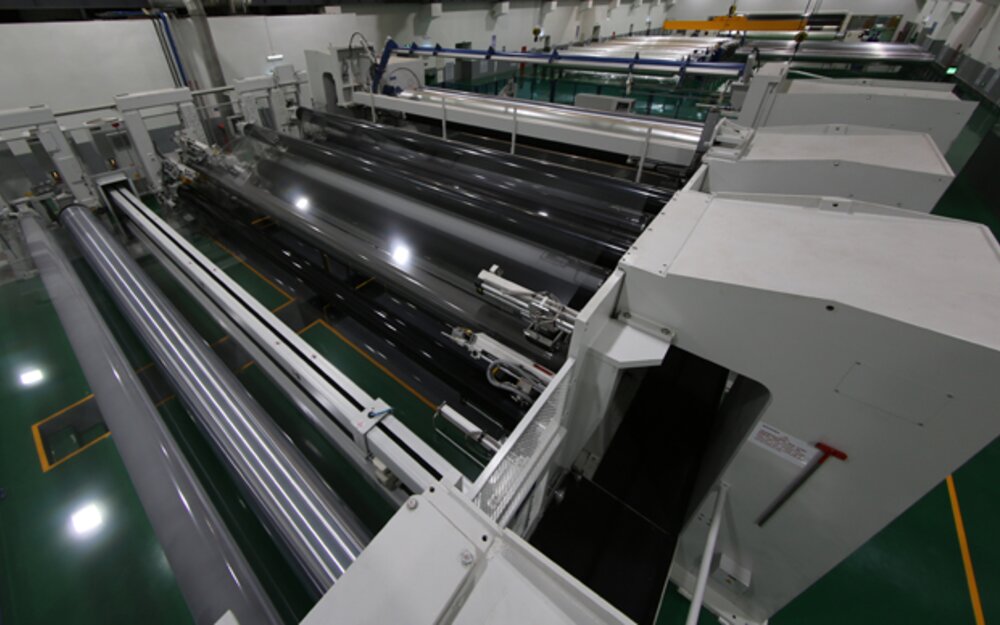

Chinese Hengli Group conquers packaging film business with a considerable line package

30 Apr 2015

Breaking into a new market with consistent production, great efficiency and high-value products

When thinking about diversification, Hengli Group’s subsidiary Yingkou Kanghui Petrochemical Co., Ltd., was thinking big: they teamed up with Brückner and ordered six BOPET packaging film lines, applying direct film casting technology, a corresponding regranulation plant and one BOPET thick film line. Recently, the last film stretching line out of this exceptional package started successfully – as all the others before. Yingkou Kanghui Petrochemical is now able to offer BOPET packaging films in a wide thickness range up to 188µm. The decision for the direct film casting technology without main extrusion brings decisive benefits such as savings in transport, logistics and personnel costs and highest efficiency in energy use – overall a clear reduction of the production costs. Together with an inherent commitment to quality all this helped the company to successfully enter the challenging plastics film business. Yingkou Kanghui Petrochemical’s Managing Director Mr. Liu Jian says: „We are very happy that we have mastered this huge project together with Brückner within our time schedule. The demanding integration of poly-condensation, stretching line and regranulation system was perfectly performed. The fact that the stretching lines have been running 100% reliably is essential for the successful operation of the direct film casting technology – so our expectations in Brückner have been fully met. Also, the day-to-day cooperation was smooth and characterized by mutual trust and respect. We look forward to further joint projects.” Hengli Group, established in 1994, is one of the largest weaving and yarn manufacturing enterprises in the world. At present, the group has more than 36,000 employees. Their subsidiary Yingkou Kanghui Petrochemical is a global leader in the field of PBT resin and one of China’s largest PET producers. The multi-billion investment in film stretching technology makes the company a big player in the film production business right from the start. 中国恒力集团以相当大的生产线组合来征服薄膜包装行业 打入一个新市场,稳定的生产,更高的效率和高价值产品 考虑到公司的多元化发展,恒力集团的子公司营口康辉石化有限公司,雄心勃勃大处着眼:他们与布鲁克纳合作并订购了6 条BOPET包装薄膜生产线,采用直接铸膜技术,相应的再造粒装置和一条BOPET厚膜生产线。最近,这个史无前例项目包的最后一条生产线,如同之前的生产线一样 – 顺利成功地投产了。 营口康辉石化目前能够提供的BOPET包装薄膜能涵盖很广的厚度范围,可达188μm。对于采用直接流延铸膜技术不采用主挤出机的决定带来举足轻重的好处,如节省运输、物流和人力成本,以及能源利用效率最高 - 整体生产成本明显降低。再加上一直以来对质量的承诺,这一切都帮助了该公司顺利进入充满挑战的塑料薄膜行业。 营口康辉石化负责人表示:我们很高兴与布鲁克纳合作,根据项目时间表计划推进这个庞大的工程,将要求极高的聚合装置、拉伸生产线和再造粒系统完美抵集合。事实上,拉伸线运行稳定可靠, 直接流延铸膜技术对成功的运行是至关重要的,达到与布鲁克纳合作预期。同时,日常的合作顺利,彼此相互信任和尊重。我们期待后续项目进一步的合作。” 恒力集团始建于1994年,是以石化,聚酯化纤、薄膜、瓶片、工程塑料,地产和织造等四大板块为主业,热电、机械、金融、酒店等多元化发展的国际型企业。集团现拥有全球单体产能最大的PTA工厂、全球最大的功能性纤维生产基地、全球最大的织造企业,员工6万多人,建有国家“企业技术中心”,企业竞争力和产品品牌价值均列国际行业前列。其子公司营口康辉石化是PBT树脂领域的全球领导者以及中国最大的BOPET生产商之一。在薄膜拉伸技术的数十亿的投资,使该公司从一开始在生产薄膜业务占据优势地位。